Friction stir welding (FSW) has revolutionized the joining of dissimilar materials, offering unprecedented opportunities in manufacturing and engineering. This solid-state welding technique, which uses mechanical stirring to create high-quality welds without melting the base materials, has become increasingly crucial in industries such as aerospace, automotive, and marine engineering. As the demand for lightweight, high-performance structures grows, FSW continues to evolve, pushing the boundaries of what's possible in material joining.

Fundamentals of Friction Stir Welding for Dissimilar Materials

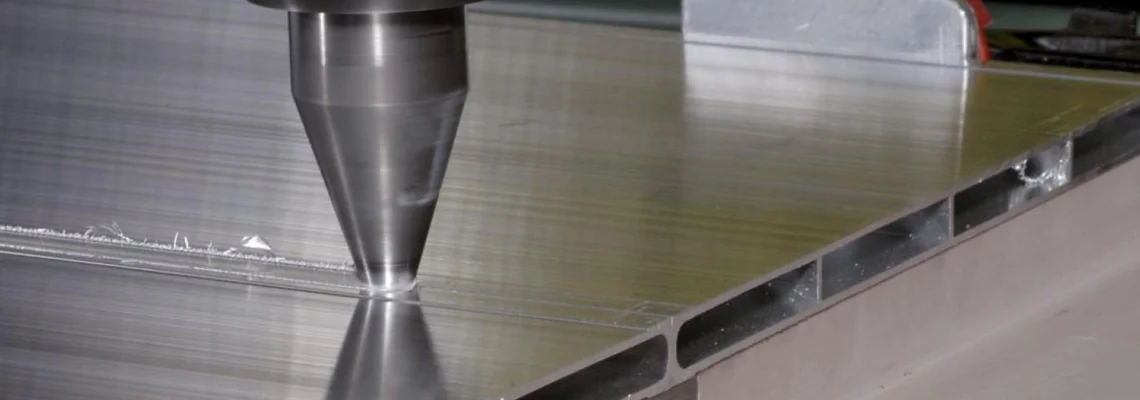

FSW for dissimilar materials involves a complex interplay of mechanical, thermal, and metallurgical processes. The technique utilizes a rotating tool with a specially designed pin and shoulder to generate frictional heat and create a plasticized region at the interface of two different materials. This process allows for the formation of a solid-state bond without reaching the melting point of either material, which is particularly advantageous when joining materials with vastly different melting temperatures or thermal properties.

One of the key advantages of FSW for dissimilar materials is its ability to minimize the formation of brittle intermetallic compounds, which are often a significant challenge in traditional fusion welding techniques. The solid-state nature of FSW also helps reduce issues related to solidification cracking, porosity, and distortion that are common in conventional welding methods.

The success of FSW for dissimilar materials hinges on careful control of process parameters, including tool rotation speed, traverse speed, and axial force. These parameters must be optimized to achieve the right balance of heat generation and material flow for each specific material combination. Proper parameter selection is crucial for achieving a homogeneous microstructure and optimal mechanical properties in the weld zone.

Material Selection and Compatibility in FSW Joints

The selection of materials for FSW joints is a critical consideration that significantly impacts the weld quality and performance. When joining dissimilar materials, it's essential to consider not only the individual properties of each material but also their compatibility and behavior when combined under the FSW process conditions.

Thermal and Mechanical Property Considerations

The thermal and mechanical properties of the materials being joined play a crucial role in the FSW process. Differences in melting points, thermal conductivity, and coefficient of thermal expansion can lead to challenges in achieving a uniform weld. For example, when joining aluminum to steel, the significant difference in melting points (660°C for aluminum vs. 1538°C for steel) requires careful control of heat input to avoid melting the aluminum while ensuring sufficient plasticization of the steel.

Mechanical properties such as yield strength, hardness, and ductility also influence the FSW process. Materials with vastly different strengths may require asymmetric tool designs or precise positioning to ensure proper material flow and mixing. The selection of which material to place on the advancing side versus the retreating side can significantly impact weld quality and strength.

Intermetallic Compound Formation at Interfaces

One of the most significant challenges in FSW of dissimilar materials is the formation of intermetallic compounds (IMCs) at the weld interface. These compounds, which form due to the reaction between different elements in the base materials, can significantly affect the mechanical properties and performance of the weld. For instance, in aluminum-steel joints, the formation of brittle Fe-Al intermetallics can lead to reduced joint strength and poor ductility.

Optimization of Material Positioning in Weld Setup

The positioning of materials in the FSW setup can significantly influence the weld quality and properties. In dissimilar FSW, the decision of which material to place on the advancing side versus the retreating side is crucial. Generally, it's recommended to place the harder or higher-melting-point material on the advancing side, as this helps to promote better material mixing and reduces the risk of defects.

For example, in aluminum-magnesium joints, placing the aluminum on the advancing side typically results in better weld quality due to its higher strength and melting point compared to magnesium. However, the optimal configuration can vary depending on the specific material combination and desired weld properties, necessitating careful experimentation and analysis for each application.

Advanced Tool Designs for Dissimilar FSW

Tool design plays a pivotal role in the success of FSW for dissimilar materials. As the field has evolved, researchers and engineers have developed increasingly sophisticated tool designs to address the unique challenges posed by joining different materials. Research and development FSW efforts have led to significant advancements in tool geometry, materials, and features.

Asymmetric and Adjustable Pin Profiles

Traditional FSW tools with symmetric pin profiles often struggle to achieve optimal material flow when joining dissimilar materials with different flow stresses. To address this, asymmetric pin profiles have been developed, featuring designs such as threaded, tapered, or stepped geometries. These profiles create a more complex flow pattern, enhancing material mixing and reducing the likelihood of defect formation.

Adjustable pin tools represent another significant advancement, allowing for real-time modification of pin length or geometry during the welding process. This adaptability is particularly beneficial when welding materials with different thicknesses or when transitioning between different material combinations.

Multi-Material and Composite Tool Compositions

The development of tools made from multiple materials or composites has expanded the capabilities of FSW for dissimilar joints. For instance, tools with a steel shank and a tungsten carbide pin offer a combination of toughness and wear resistance, crucial for joining high-strength alloys or abrasive materials.

Composite tools, such as those reinforced with ceramic particles or coated with advanced materials like polycrystalline cubic boron nitride (PCBN), provide enhanced thermal stability and wear resistance. These properties are especially valuable when welding materials with high melting points or those prone to tool wear.

Thermal Management Features in Tool Design

Effective thermal management is critical in FSW of dissimilar materials, particularly when joining materials with significantly different thermal properties. Advanced tools now incorporate features designed to control heat generation and dissipation, such as:

- Scrolled shoulders that improve material flow and heat distribution

- Cooling channels within the tool body for active temperature control

- Thermal barrier coatings to manage heat transfer between the tool and workpiece

These thermal management features allow for more precise control over the welding process, enabling the joining of materials with vastly different melting points or thermal conductivities.

Adaptive Tool Systems for Process Control

The latest advancements in FSW tool technology include adaptive systems that can respond to changing conditions during the welding process. These systems utilize real-time feedback from sensors monitoring parameters such as temperature, torque, and force to adjust tool position, rotation speed, or other variables automatically.

Adaptive tools are particularly valuable in dissimilar FSW, where material properties can vary significantly across the weld zone. By continuously optimizing process parameters, these systems can maintain consistent weld quality even when faced with variations in material thickness, composition, or properties.

Process Parameter Optimization for Heterogeneous Joints

Optimizing process parameters is crucial for achieving high-quality friction stir welds in dissimilar materials. The complex interactions between different materials during FSW necessitate careful selection and control of welding parameters to ensure optimal joint properties.

Rotational and Traversing Speed Correlations

The relationship between tool rotational speed and traversing speed plays a significant role in determining the heat input and material flow during FSW. For dissimilar materials, finding the right balance is critical to ensure sufficient plasticization of both materials without overheating or underheating either one.

Generally, higher rotational speeds generate more heat, which can be beneficial when joining materials with significantly different melting points. However, excessive heat input can lead to undesirable microstructural changes or the formation of brittle intermetallic compounds. Conversely, higher traversing speeds reduce heat input but may result in insufficient material mixing if not properly balanced with rotational speed.

Researchers have employed various approaches to optimize these parameters, including:

- Design of experiments (DOE) techniques such as response surface methodology (RSM)

- Computational modeling using finite element analysis (FEA) and computational fluid dynamics (CFD)

- Machine learning algorithms for predicting optimal parameter combinations

Axial Force and Plunge Depth Calibration

The axial force applied to the FSW tool and the plunge depth of the tool pin are critical parameters that affect weld quality in dissimilar joints. These parameters must be carefully calibrated to ensure proper material flow and consolidation while avoiding excessive flash formation or tool wear.

For materials with significantly different strengths or hardnesses, a stepped plunge depth profile may be employed. This approach involves using a deeper plunge on the softer material side to promote better mixing and prevent defects at the interface.

Advanced FSW systems now incorporate force-controlled welding, which automatically adjusts the plunge depth to maintain a constant axial force throughout the weld. This capability is particularly valuable when welding materials with varying thicknesses or properties along the weld line.

Thermal Input Control Strategies

Controlling thermal input is crucial in FSW of dissimilar materials, especially when joining materials with vastly different thermal properties. Strategies for thermal input control include:

- Pulsed FSW: Alternating between high and low rotational speeds to create a cyclic heating and cooling pattern

- Hybrid FSW processes: Combining FSW with additional heat sources (e.g., laser-assisted FSW) or cooling methods (e.g., cryogenic cooling)

- Temperature-controlled FSW: Using real-time temperature feedback to adjust process parameters dynamically

- Tool design modifications: Incorporating features like cooling channels or thermal barrier coatings to manage heat distribution

These thermal control strategies help maintain optimal welding conditions throughout the process, ensuring consistent weld quality and minimizing the risk of defect formation or undesirable microstructural changes.

Microstructural Evolution in Dissimilar FSW Joints

The microstructural evolution in dissimilar friction stir welds is a complex process that significantly influences the mechanical properties and performance of the joint. Understanding these microstructural changes is essential for optimizing the FSW process and predicting joint behavior under various loading conditions.

In dissimilar FSW joints, the weld zone typically consists of several distinct regions:

- Stir zone (SZ): The region of intense plastic deformation and material mixing

- Thermomechanically affected zone (TMAZ): The area adjacent to the SZ, experiencing both thermal and mechanical effects

- Heat-affected zone (HAZ): The region affected only by heat, without significant mechanical deformation

The stir zone of dissimilar FSW joints often exhibits a complex, layered structure with alternating bands of the two base materials. The degree of material mixing and the resulting microstructure are heavily influenced by the welding parameters, tool design, and material properties. Advanced characterization techniques such as transmission electron microscopy (TEM) and atom probe tomography (APT) have revealed the formation of nanoscale intermetallic compounds at the interface between dissimilar materials.

Grain refinement is a common feature observed in the stir zone of FSW joints, resulting from the severe plastic deformation and dynamic recrystallization processes during welding. However, the extent of grain refinement can vary significantly between the two materials being joined due to differences in their recrystallization behavior and thermal properties.

The TMAZ in dissimilar FSW joints presents unique microstructural characteristics due to the different responses of the base materials to the thermal and mechanical cycles during welding. This region often exhibits a gradient in grain size and orientation, with the microstructure transitioning from the highly deformed stir zone to the less affected base material.

Understanding and controlling these microstructural changes is crucial for optimizing the FSW process and achieving desired joint properties in dissimilar material combinations.

Mechanical Performance and Failure Mechanisms

The mechanical performance of dissimilar FSW joints is a critical consideration for their application in various industries. The unique microstructure and material combinations in these joints can lead to complex mechanical behavior and failure mechanisms that differ significantly from those observed in similar material welds.

Tensile and Fatigue Behavior of Dissimilar Welds

The tensile strength of dissimilar FSW joints is often influenced by the strength mismatch between the base materials and the properties of the weld zone. In many cases, the joint efficiency (ratio of joint strength to the strength of the weaker base material) can exceed 80%, demonstrating the effectiveness of FSW for joining dissimilar materials.

Fatigue performance is another crucial aspect, particularly for applications in aerospace and automotive industries. Dissimilar FSW joints often exhibit improved fatigue resistance compared to fusion-welded joints due to the absence of solidification defects and the refined microstructure in the weld zone. However, the fatigue behavior can be complex, with crack initiation and propagation paths influenced by the heterogeneous microstructure at the weld interface.

Fracture Toughness and Crack Propagation Paths

The fracture toughness of dissimilar FSW joints is influenced by the complex microstructure and potential presence of intermetallic compounds at the interface. Crack propagation paths in these joints can be intricate, often deviating along the interface between the two materials or following regions of microstructural weakness.

Researchers have employed advanced techniques such as digital image correlation (DIC) and in-situ testing to study crack initiation and propagation in dissimilar FSW joints. These studies have revealed that the heterogeneous microstructure can lead to mixed-mode fracture behavior and complex crack paths that are highly dependent on the specific material combination and welding parameters.

Residual Stress Distribution and Management

Residual stresses in dissimilar FSW joints can significantly impact their mechanical performance and long-term reliability. The distribution of residual stresses in these joints is often asymmetric due to the different thermal and mechanical properties of the base materials.

Techniques for managing residual stresses in dissimilar FSW joints include:

- Post-weld heat treatments to relieve internal stresses

- Optimization of welding parameters to minimize stress generation

- Use of specialized clamping systems or fixture designs to control workpiece deformation

- Application of stress engineering techniques such as local mechanical tensioning

Effective management of residual stresses is crucial for ensuring the dimensional stability and long-term performance of dissimilar FSW joints, particularly in applications subject to cyclic loading or extreme environmental conditions.

Corrosion Resistance of Heterogeneous Interfaces

The corrosion resistance of dissimilar FSW joints is a critical factor in determining their long-term performance, especially in harsh environments. The heterogeneous nature of these joints can lead to complex corrosion behavior, often differing significantly from that of the individual base materials.

One of the primary challenges in dissimilar FSW joints is the potential formation of galvanic couples between the different materials, which can accelerate corrosion processes. For example, in aluminum-steel joints, the significant difference in electrochemical potential between the two metals can lead to preferential corrosion of the more anodic aluminum.

The microstructural changes induced by the FSW process can also impact corrosion behavior. The refined grain structure in the stir zone often exhibits improved corrosion resistance compared to the base materials. However, the presence of intermetallic compounds at the interface can create localized areas susceptible to corrosion attack.

Researchers have employed various strategies to enhance the corrosion resistance of dissimilar FSW joints:

- Optimization of welding parameters to minimize the formation of detrimental intermetallic phases

- Application of post-weld surface treatments such as laser surface melting or shot peening

- Use of corrosion-resistant interlayer materials to isolate dissimilar metals

- Development of specialized coatings tailored for the heterogeneous weld zone

Advanced characterization techniques, including electrochemical impedance spectroscopy (EIS) and scanning electrochemical microscopy (SECM), have provided valuable insights into the localized corrosion behavior of dissimilar FSW joints. These studies have revealed that the corrosion resistance can vary significantly across different regions of the weld, necessitating a comprehensive approach to corrosion protection.